If you’ve ever ventured into the world of hydraulic systems, you’ve likely encountered hydraulic hoses. These essential components play a crucial role in transmitting power within hydraulic machinery. Understanding how hydraulic hoses are measured is fundamental knowledge for anyone dealing with hydraulic systems. In this article, we’ll break down the intricacies of hydraulic hose measurements in a simple and engaging manner. This content is presented by Healthyhouseplans.com.

Unraveling the Basics of Hydraulic Hose Measurement

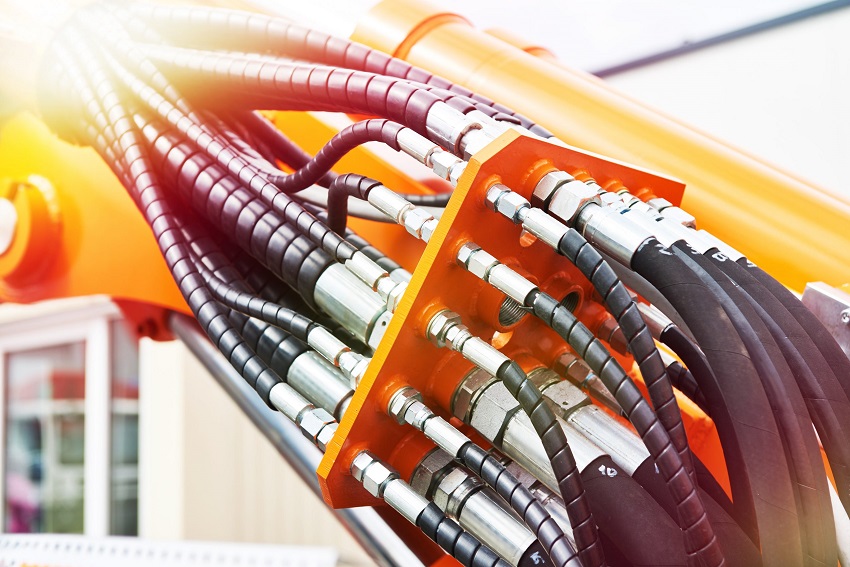

Picture this: a hydraulic system is akin to a circulatory system, with hydraulic hose serving as the veins, carrying hydraulic fluid to various components. Just as knowing your blood pressure and cholesterol levels is vital for your health, understanding hydraulic hose measurements is crucial for maintaining a well-functioning hydraulic system.

The Anatomy of a Hydraulic Hose: Inner Diameter, Outer Diameter, and More

Hydraulic hoses consist of several key components, each contributing to their performance. The inner diameter (ID) and outer diameter (OD) are two primary measurements that play a significant role in hose sizing. Think of the ID as the pathway through which hydraulic fluid flows and the OD as the protective layer that shields the hose from external damage.

Measuring Hydraulic Hose Length: From End to End

Hydraulic hose length is a straightforward measurement, yet precision is essential. To measure the length accurately, extend the hose in a straight line from end to end and measure it against a tape measure or ruler. This measurement is vital when replacing hoses or installing new ones.

Navigating Dash Sizes: Decoding the Numeric System

Dash sizes might sound like a futuristic concept, but they are the industry’s way of standardizing hose sizes. These numeric designations are often seen on hose fittings and help ensure compatibility between different components of the hydraulic system.

SAE Standards: Simplifying Hose Measurement Practices

The Society of Automotive Engineers (SAE) has established guidelines for hydraulic hose measurements, making it easier for manufacturers and users to identify compatible hoses. These standards ensure that hoses from different manufacturers can work seamlessly together.

Factors Affecting Hose Measurements: Temperature, Pressure, and Compatibility

Hydraulic systems operate in a wide range of conditions, from scorching heat to freezing cold. Temperature fluctuations can affect the size and flexibility of hoses, impacting their performance. Additionally, the pressure within the hydraulic system influences the choice of hose size and material.

Selecting the Right Hose: Balancing Size and Application

Choosing the right hydraulic hose involves a careful balance between size and application. A hose that’s too narrow might restrict fluid flow, while one that’s too wide could lead to excessive fluid leakage. Assessing factors like pressure rating, temperature range, and compatibility with hydraulic fluid is essential.

You may also like: Where Can I Buy Screws for the IKEA Grundtal Shelf?

Steps to Properly Measure a Hydraulic Hose

- Identify the Hose Type: Different hydraulic hoses are designed for specific applications. Identify the type of hose you need before proceeding.

- Measure Inner Diameter: Using a caliper, measure the inner diameter of the hose. This measurement is crucial for selecting fittings and ensuring proper fluid flow.

- Measure Outer Diameter: Similar to the inner diameter, the outer diameter measurement helps determine hose compatibility and protection.

- Check Dash Size: If your hose has dash sizing, confirm its compatibility with the fittings you intend to use.

- Consider Length: Measure the hose length accurately from end to end, considering any bends or curves it might have.

Maintenance Tips: Ensuring Longevity of Hydraulic Hoses

Proper maintenance of hydraulic hoses prolongs their lifespan and ensures the system’s efficiency. Regularly inspect hoses for signs of wear, such as cracks, bulges, or leaks. Additionally, protect hoses from exposure to extreme temperatures and abrasive materials.

Conclusion

In the world of hydraulic systems, understanding how hydraulic hoses are measured is a fundamental skill. By grasping concepts like inner and outer diameter, dash sizes, and SAE standards, you’re better equipped to select the right hose for any application. Remember, hydraulic systems thrive on precision, and accurate hose measurements play a pivotal role in their smooth operation.

FAQs

Q: Can I use a hose with a slightly different outer diameter than recommended?

A: It’s best to stick to recommended measurements to ensure proper compatibility and performance.

Q: How often should I inspect hydraulic hoses for wear and tear?

A: Regular visual inspections should be conducted at least monthly, with more frequent checks in demanding environments.

Q: Are there specific tools for measuring dash sizes on hoses?

A: Yes, calipers designed for hydraulic fittings can accurately measure dash sizes.

Q: Can I replace a hydraulic hose with a longer one if needed?

A: While it’s possible, changing hose length could impact the system’s overall performance. Consult with a professional before making changes.

Q: Is it essential to adhere to SAE standards for hydraulic hoses?

A: Following SAE standards ensures compatibility and safety within hydraulic systems, making it a recommended practice.